A new proposal combining the need for reduced size with high performance, making the most of the sturdy aspects of steel, the consolidated technology of the wire condenser and the innovative multi-circuit opportunity which allows COMPACT to showcase itself as the ideal heat exchanger for a wide range of applications, opening up to the natural solution of new design challenges such as new refrigerants, high operating pressures, product recyclability and, last by not least, the absence of maintenance required during the lifespan of the household appliance.

COMPACT: the innovative heat exchanger

designed to meet your needs!

With our Configurator,

satisfying your bespoke request

will be even easier and faster.

Fill in the sections and you will be able to go ahead

in complete autonomy with your request to create

the exchanger you need, by features and characteristics.

Click below to access the configuration!

START THE CONFIGURATION

"*" indicates required fields

temperings

loss of load

modularity

modularity

Fewer temperings

Fewer temperings and the subsequent reduction in the risk of loss of refrigerant, without impairing the efficiency of the heat exchanger, increases the tenacity over time of the product’s performance.

Maximisation of the concentration of primary and secondary surfaces in the unit of space means the Cu/Al exchanger in use can be replaced with our solution without the customer having to review the project and means a steel solution can be applied where previously it would have been impossible.

Reduction in loss of load

where necessary

This means the circuit can be doubled and/or several circuits can be created on layers of the same exchanger, to achieve the performance required by the equipment.

Modularity and size scalability

The expansion in height, length and width can be achieved both with the size variation of the individual position, and by implementing positions inserted in the securing system specifically designed as being symmetrical, and by interconnecting the modules, by unifying several securing systems with one another, in a repeatable and scalable fashion.

Circuit flexibility

- Option to connect all the positions in a line.

- Several circuits on a single module, with line/parallel and/or parallel/parallel connections.

- Option of replicating the union of the various individual modules in different diagrams.

- Option of diversifying the flows and differentiating and/or multiplying the circuits by connections in line and parallel, while keeping the overall size unaltered.

Ottima manutenibilità e resistenza al deposito di elementi esterni

convogliati da flussi di aria sono le principali caratteristiche del nostro prodotto.

All the JOINTS undergo a 100% helium test to check for leaks.

The possibility of setting the spaces between the rows and their position with regard to the next layers, ELIMINATE the possibility of dust DEPOSITS/ACCUMULATION or that of other substances which could reduce or even block the air flow.

In general, there are 65% FEWER JOINTS, compared to a Cu/Al exchanger. This not only cuts costs but also improves life performance.

The product is characteristically ROBUST and has no issues with accidental impacts or damage due to surface “cleaning”.

RESISTANCE OVER TIME is, by now, driver essential.

Ottima manutenibilità e resistenza al deposito di elementi esterni

convogliati da flussi di aria sono le principali caratteristiche del nostro prodotto.

Excellent maintenance and resistance to the deposit of external elements transported by air flow

- All the JOINTS undergo a 100% helium test to check for leaks.

- The possibility of setting the spaces between the rows and their position with regard to the next layers, ELIMINATE the possibility of dust DEPOSITS/ACCUMULATION or that of other substances which could reduce or even block the air flow.

- In general, there are 65% FEWER JOINTS, compared to a Cu/Al exchanger. This not only cuts costs but also improves life performance.

- The product is characteristically ROBUST and has no issues with accidental impacts or damage due to surface “cleaning”.

- RESISTANCE OVER TIME is, by now, driver essential.

All the JOINTS undergo a 100% helium test to check for leaks.

The possibility of setting the spaces between the rows and their position with regard to the next layers, ELIMINATE the possibility of dust DEPOSITS/ACCUMULATION or that of other substances which could reduce or even block the air flow.

In general, there are 65% FEWER JOINTS, compared to a Cu/Al exchanger. This not only cuts costs but also improves life performance.

The product is characteristically ROBUST and has no issues with accidental impacts or damage due to surface “cleaning”.

RESISTANCE OVER TIME is, by now, driver essential.

Ottima manutenibilità e resistenza al deposito di elementi esterni

convogliati da flussi di aria sono le principali caratteristiche del nostro prodotto.

All the JOINTS undergo a 100% helium test to check for leaks.

The possibility of setting the spaces between the rows and their position with regard to the next layers, ELIMINATE the possibility of dust DEPOSITS/ACCUMULATION or that of other substances which could reduce or even block the air flow.

Il numero delle GIUNZIONI presenti mediamente

è il 65% IN MENO, rispetto ad uno scambiatore Cu/al.

Questo oltre a ridurre i costi garantisce

una migliore life performance.

The product is characteristically ROBUST and has no issues with accidental impacts or damage due to surface “cleaning”.

RESISTANCE OVER TIME is, by now, driver essential.

100% recyclable

Both the tube and the wires are made of carbon steel.

Steel is the most recycled material in the world and therefore has an inherent inclination towards the circular economy, a crucial aspect for mitigating CO2 emissions and combating climate change.

For the Marcegaglia Group, sustainability is not only an opportunity but also a tangible commitment to addressing the challenges of a world increasingly sensitive to environmental and social impacts, in order to ensure a better future for future generations.

With this purpose in mind, Marcegaglia has developed a Sustainability Plan, a Group roadmap to reconcile business growth and financial stability with environmental and social responsibility.

Download the Marcegaglia Sustainability Report here

discover our products for the professional refrigeration industry

Features

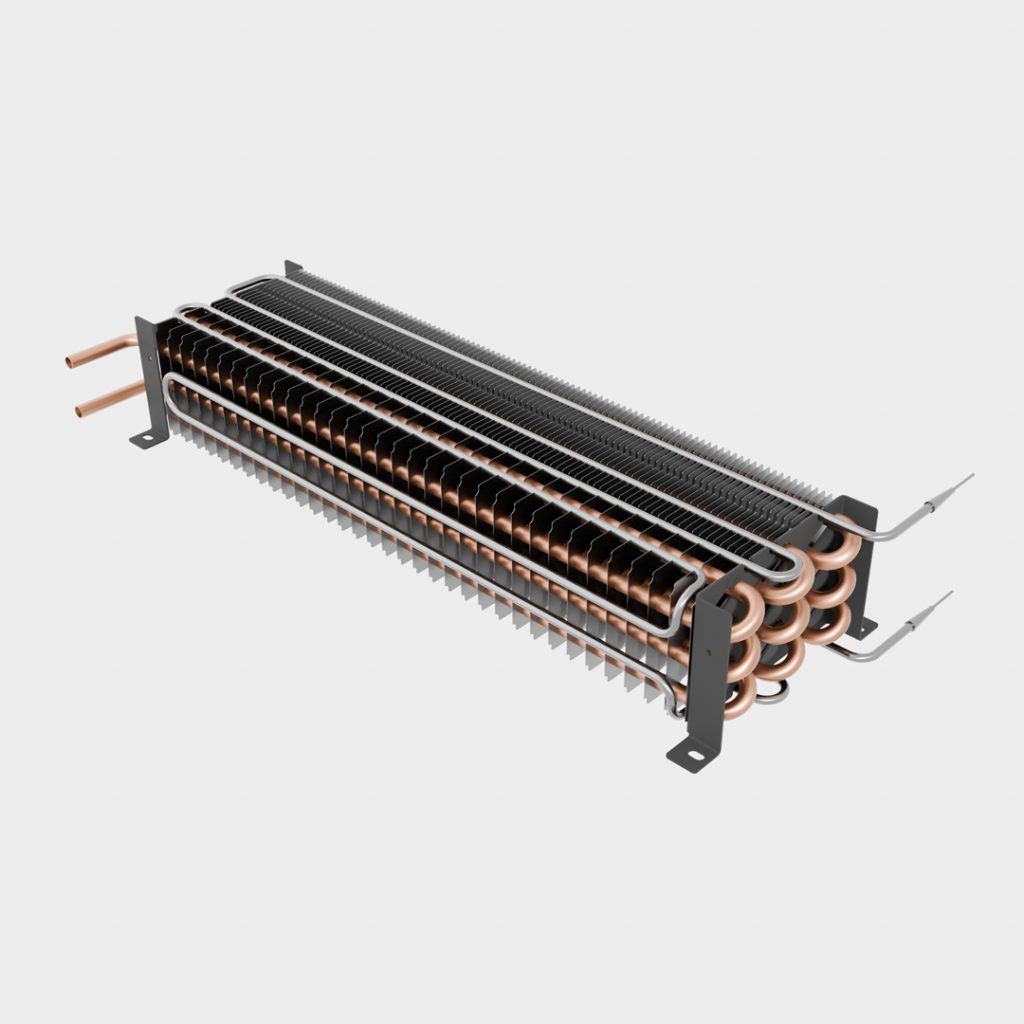

Serpentine with electric welded wires on both sides

- Steel tube: UNI EN 10139-DC04

- Serpentine pitch: 50 - 40 - 25 mm

- Wire area width: 350 - 1,000 mm

- Wire height: 300 - 1,450 mm

- Cold-drawn steel wires 3CD 5 UNI 5598-71

- Distance between the wires: decided together with the customer

- Paint: Black cataphoresis

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

Fixing system

- Su richiesta, saldatura spalle di fissaggio in acciaio FeP01 UNI 5961-67, disponibili in diverse altezze e forature

(Range altezze spalla: da 0 a 25 mm).

On demand

- Application of Cu dehydrator filter

- Application of Cu leakage tube

- Welding tests with 100% He technology

- Application of fixation brackets

Features

"Sandwich" serpentine

between electro-welded steel sheets

- Steel tube: UNI EN 10139-DC04

- Serpentine pitch: 60 - 32.5 mm

- Wire area width: 342 - 780 mm

- Wire height:: 240 - 1,456 mm

- Steel plate: UNI EN 10139-DC01

- Steel sheets thickness: 0.3 - 0.4 mm

- Paint: Black cataphoresis

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

Fixing system

- Different solutions of parallel or inclined shoulders. Availability of different kind of holes on the condensers shoulders. Different heights can be achieved on the fixing shoulder.

On demand

- Application of Cu dehydrator filter

- Application of Cu leakage tube

- Welding tests with 100% He technology

- Creation of securing sides in line with the customer’s drawing

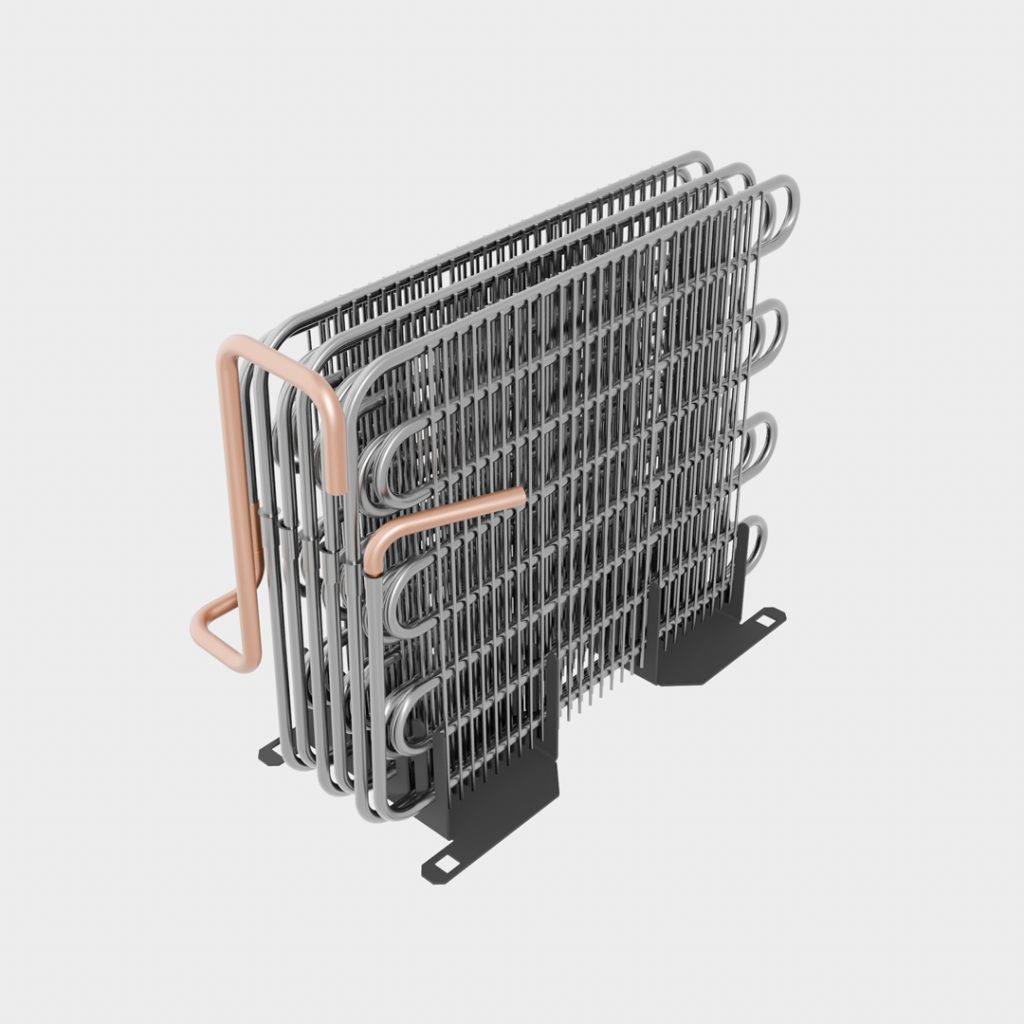

Features

Serpentine with electric welded wires on both sides

- Electro-welded carbon steel tube: acc. to UNI EN 10139-DC04

- Available tube diameters: 4.76x0.7 mm or 6.00x0.7 mm

- Serpentine pitch: 50 - 25 mm

- Bend radius: 12.5 mm

- Wire height: decided together with the customer

- Cold-drawn steel wires 3CD 5 UNI 5598-71

- Distance between the wires: decided together with the customer

- Paint: Black cataphoresis

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

Securing

- The securing rods are decided together with the customer, keeping the project needs in mind, in terms of both size as well as material and finishes.

On demand

- Application of Cu dehydrator filter

- Application of Cu stubs on Fe end tubes to make the connection easier during the client’s production process

- Welding tests with 100% He technology

- Creation of securing rods in line with customer’s drawing

- Creation of bespoke drawing

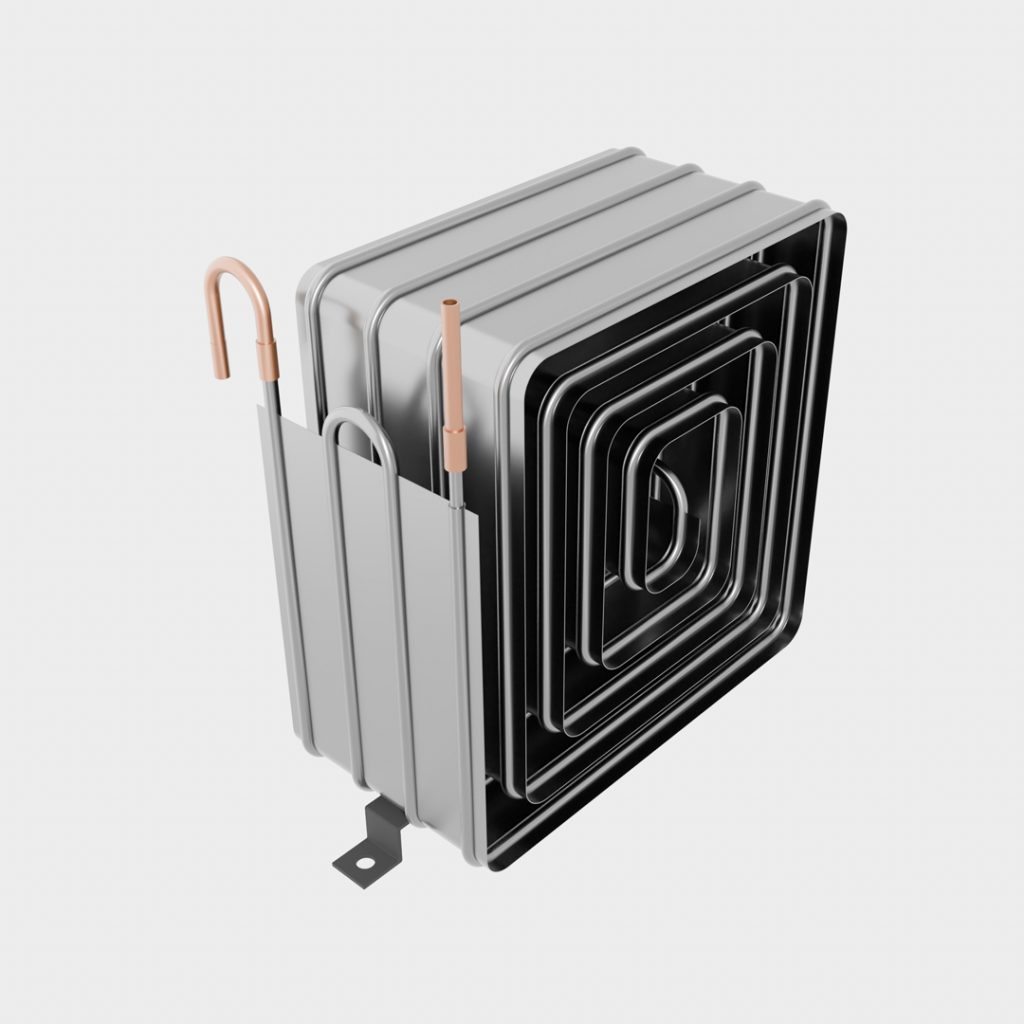

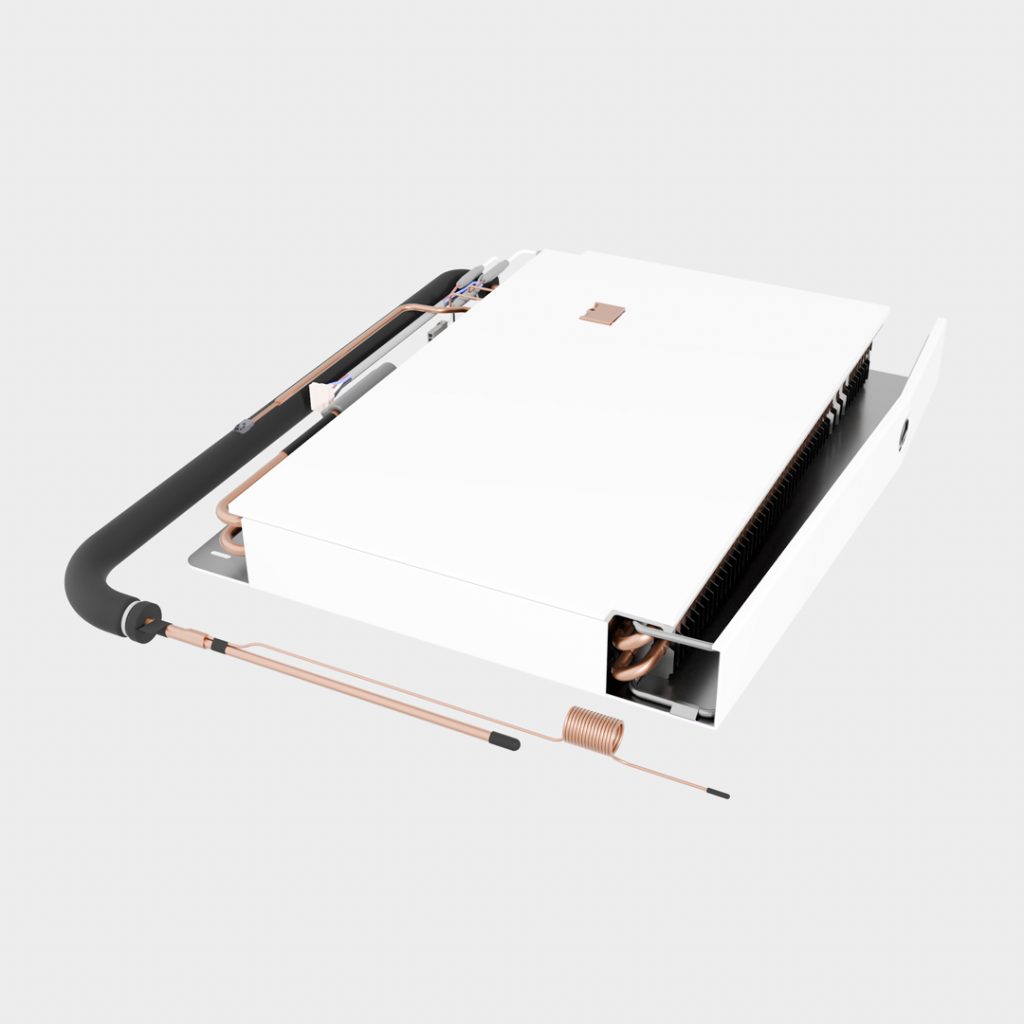

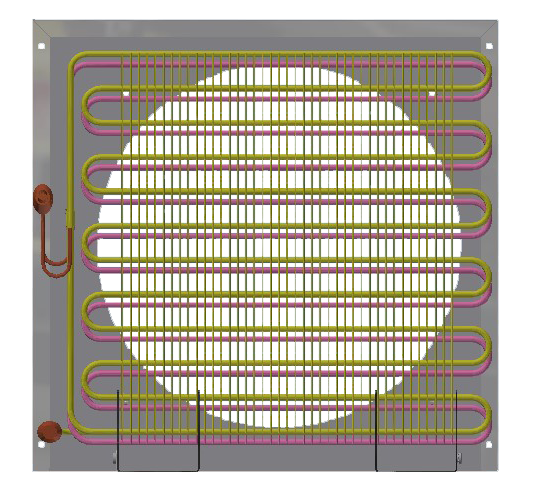

Features

"Sandwich" serpentine

between electro-welded steel sheets

- Electro-welded carbon steel tube: acc. to UNI EN 10139-DC04

- Available tube diameters: 4.76x0.70 mm or 6.00x0.7 mm

- Serpentine pitch: 32.50 mm

- Bend radius: 16.00 mm

- Height: decided together with the customer

- Steel plate: UNI EN 10139-DC01

- Steel sheets thickness: 0.3 - 0.4 mm

- Paint: Black cataphoresis

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

Securing

- The securing rods are decided together with the customer, keeping the project needs in mind, in terms of both size as well as material and finishes.

The rod element is structural and can be used, when needed, as a securing for the conveyor system casing and/or ventilator support.

On demand

- Application of Cu dehydrator filter

- Application of Cu stubs on Fe end tubes to make the connection easier during the client’s production process

- Welding tests with 100% He technology

- Creation of securing rods in line with customer’s drawing

- Creation of bespoke drawing

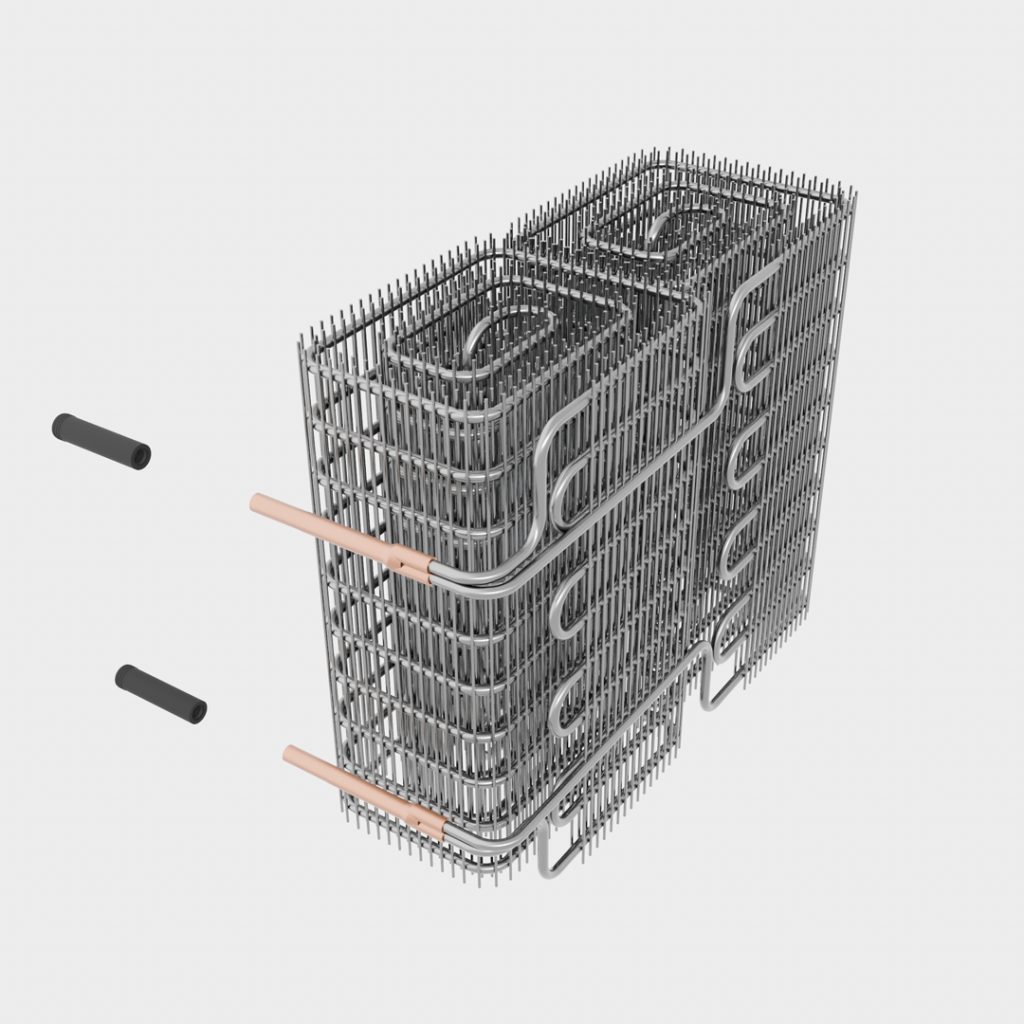

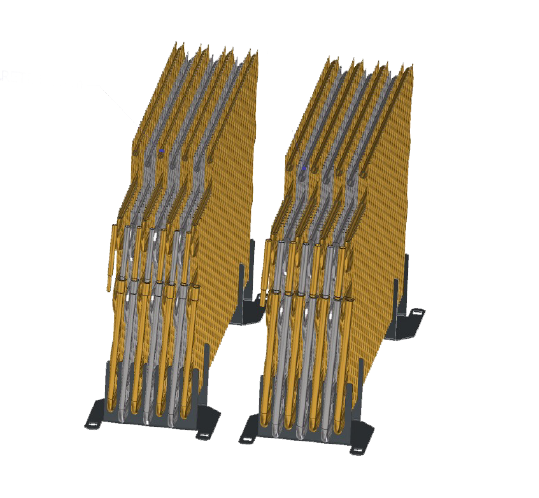

Features

Modular serpentines with electro-welded wires

on both sides

- Electro-welded carbon steel tube: acc. to UNI EN 10139-DC04

- Available tube diameters: 4.76x0.7 mm or 6.00x0.7 mm

- Serpentine pitch: 25 mm

- Bend radius: 4 mm

- Number of modules: decided together with the customer

- Number of circuits and connection: can be decided together with the customer

- Cold-drawn steel wires 3CD 5 UNI 5598-71

- Distance between the wires: decided together with the customer

- Paint: black cataphoresis and/or nano-technological coating

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

Securing

- The securing rods are decided together with the customer, keeping the project needs in mind, in terms of both size as well as material and finishes.

On demand

- Application of Cu dehydrator filter

- Application of Cu stubs on Fe end tubes to make the connection easier during the client’s production process

- Welding tests with 100% He technology

- Creation of conveyor system casing and/or ventilator support

- Creation of bespoke drawing

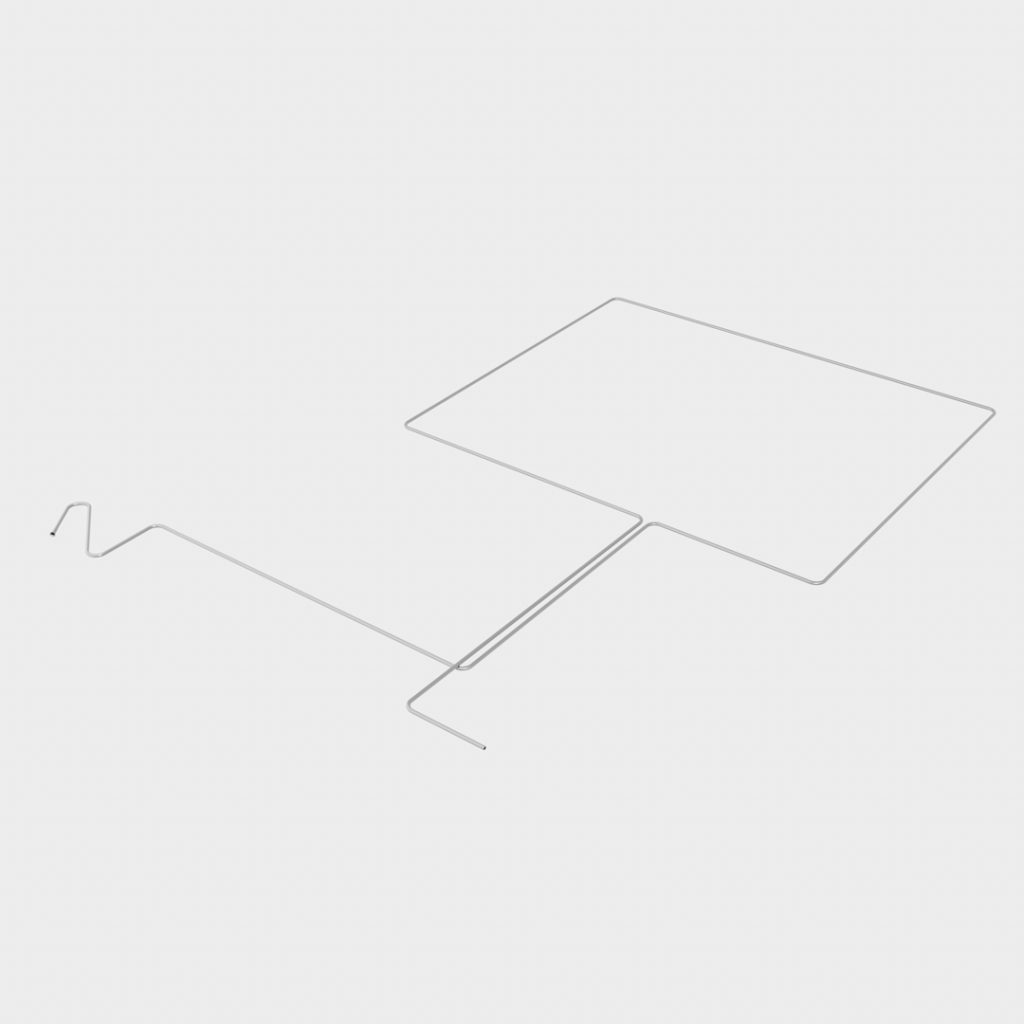

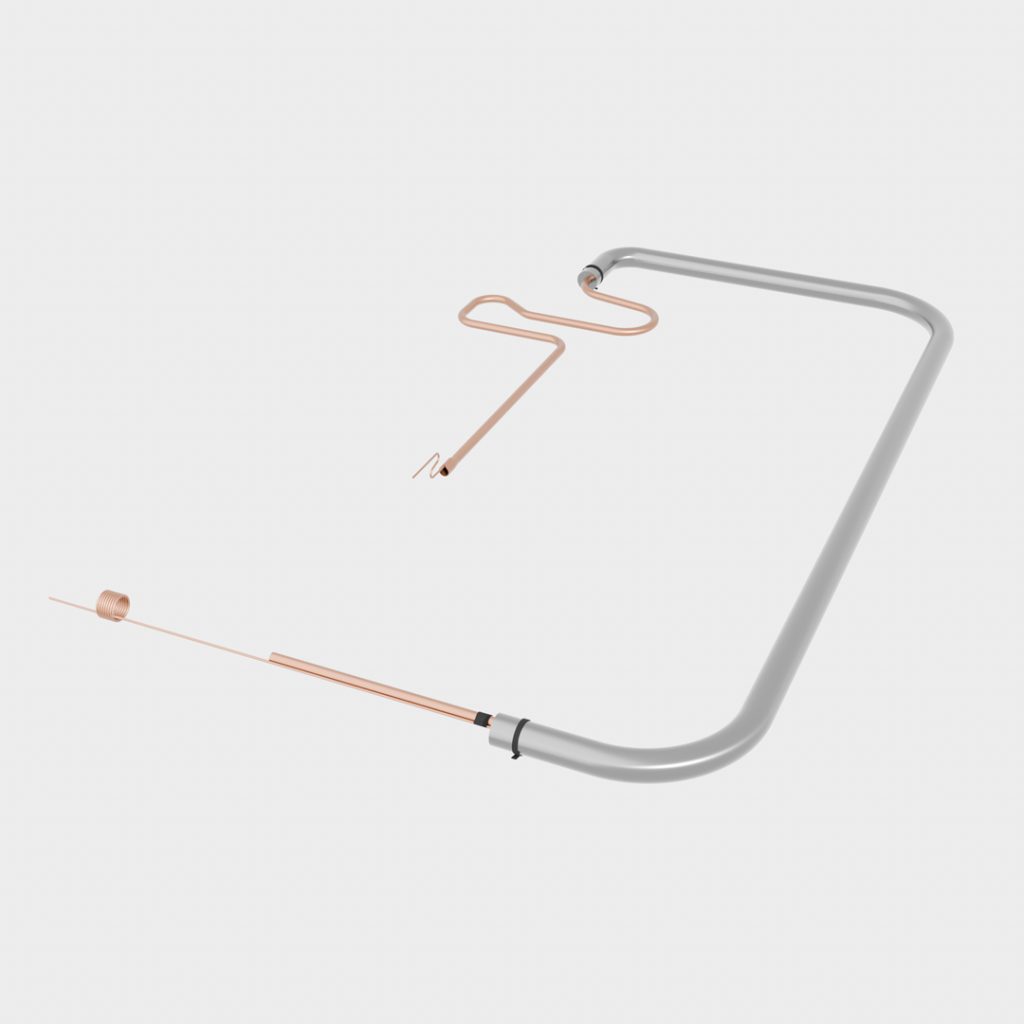

Features

- Steel tube: UNI EN 10139-DC04, hot-dip galvanized

- Standard bending diameter: 11 mm inner tube

- Maximum bar length: 7,5 m

- Design: 2D and 3D bending

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

On demand

- End tube working

- End tube zinc free

- End bending: specific upon request

Features

- Steel tube: UNI EN 10139-DC04, hot-dip galvanized

- Spiral pitch: 7 - 20 mm

- Specific internal diameter of the spiral: upon request

- Spirals centres distance: upon request

- Spiral length 80 - 300 mm

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

On demand

- Specific end bending

Features

- DHP copper tube acc. to UNI EN 12735-2.

and steel tube acc. to EN 573-3:1996 and UNI EN 755-2:1999 - Tube sizes: AL/AL tube 8.00x0.7 mm

Cu/AL tube 8.00x0.5 mm or 8.00x0.7 mm - Tube interaxle spacing pitch: 16 mm

- Wing height: 30 mm - 50 mm - 75 mm

- Wing-wing distance: 4 mm

- Winged pack size: decided together with the customer

- Circuits: number of circuits and connection to be decided together with the customer

- Cleanness and internal humidity: acc. to DIN 8964

- Saline mist: as per ASTM 8117/ISO 9227 > 48 h

On demand

- End tube working

- Application of Cu stubs to the ends

- End bending: specific upon request

- Paint: Black cataphoresis

Features

- Finned evaporator

- Fixing brackets

- Exchanger tube with capillary

- Defrosting heater

- Aluminum back plate (conveyor)

- Aluminum front plate (carter)

- EPS parts

- NTC sensors

- Thermal fuse/disjunction

- Wiring, fixing, screws, rivet

On demand

- Leakage search test with 100% He

- 100% correct wiring test

- Circuit configuration

- Capillary-capillary joints adapter

Features

- Copper tube with external diameter: 5.95 - 7.00 - 8.00 - 10.00 mm

- Aluminum tube with external diameter: 8.00 mm

- Ø e. 1.85-mm external capillary tube (with internal diameter values and expansion depending on the delivery flow)

- Orbital cut of capillary with 100% load measurement

- DHP copper acc. to UNI 5649-88, part 1

- Aluminium compliant with standard UNI 5649-88 pt.1

- Internal cleanness: acc. to DIN 8964

On demand

- Copper accumulator

- Copper adapter with external diameter: 5.95 - 7 - 8 - 10 mm

- Head treatments upon request

- Rubaflex insulating sleeve

- Capillary-capillary joints adapter

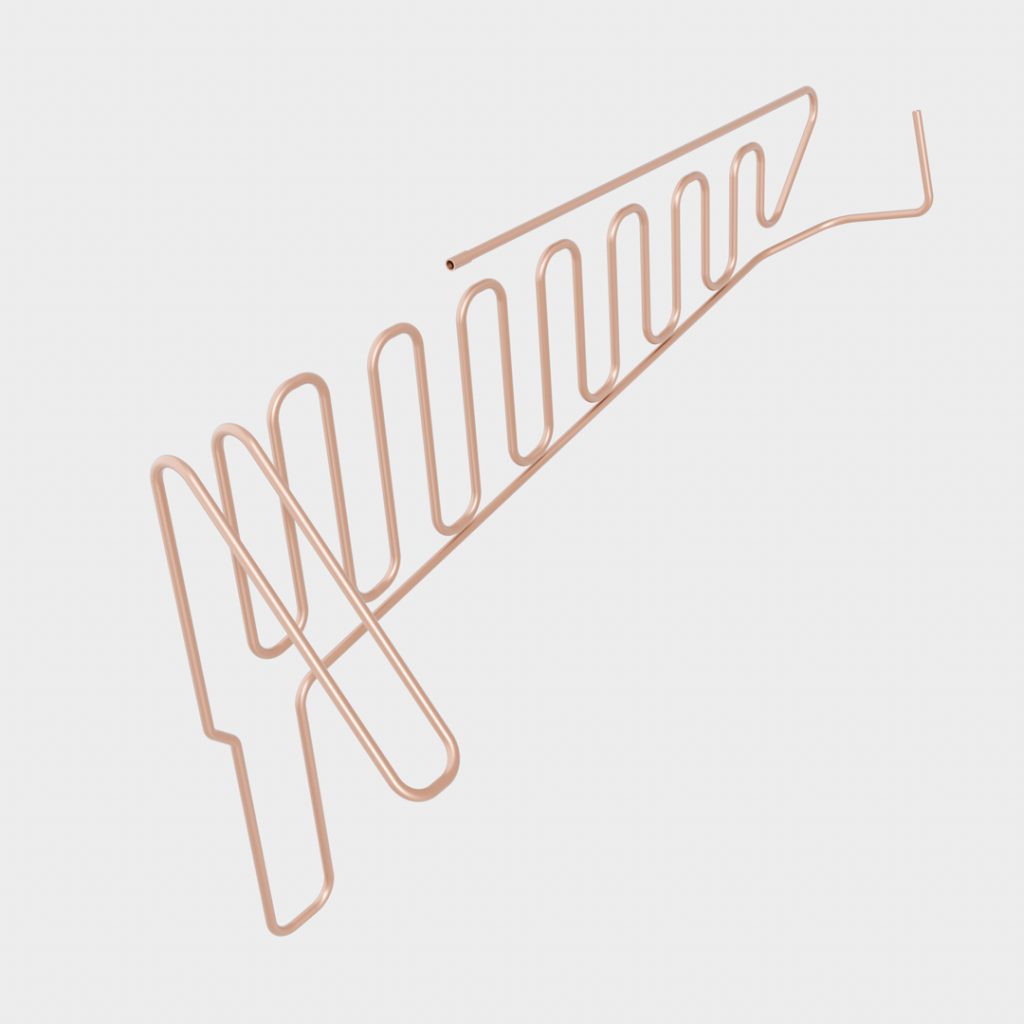

Features

- Tube of copper Cu DHP acc. to UNI 5649

- Squeezing, enlargement and tolerances acc. to DIN 7773-81

- Cleanness and internal humidity: acc. to DIN 8964

- Refrigerant compatibility: to be checked with the customer

- Diameter 5.00 mm - 10.00 mm

- Length 35 mm - 3,000 mm

On demand

- Head workings: calibration, widening, tapering and hammering

- Operations: centrifugal wash to remove internal and external residue of oil and shavings

- Packaging: decided together with the customer

Features

- Capillary tube: external Ø 1.85 mm

- Capillary tube: internal Ø, can be decided to suit customer’s given load value requirements

- Capillary length: min. 500 mm and max. 5,000 mm

- Cut: orbital technology with 100% measuring of the load

- Cu DHP type copper acc. to UNI 5649-88 pt.1

- Internal cleanness: acc. to DIN 8964

On demand

- Head workings: Cu expansion stub tempering

- Operations: creation of spirals or other pre-bends for packaging

- Packaging: decided together with the customer

Features

- Fe tube: 4.00 - 4.76 - 6.00 - 8.00 mm

- Tube: electro-welded carbon steel acc. to UNI EN 10139-DC04, hot galvanised or "black"

- Al tube: external Ø: 8.00 mm, acc. to EN 573-3:1996 and UNI EN 755-2:1999

- Cu tube: external Ø: 4.00 - 5.00 - 6.00 - 7.00 - 8.00 - 10.00 mm

- Cu DHP type copper acc. to UNI 5649-88 pt.1

- Internal cleanness: acc. to DIN 8964

On demand

- Head workings: calibration, widening, tapering and hammering

- Operations: custom design and possibility of bends even in 3D

- Packaging: decided together with the customer

Features

Surface appearence

- Non-coated condition is supplied with slight surface oil and protected ends in order to allow the storage of tubes in proper warehouses and for a reasonable period of time.

- Zinc coating with minimum thickness above 7 µ, equivalent to 50 g/m2, in order to ensure red rust corrosion resistance in salt spray equal to 48 hours, measured according to ISO 9227.

Guaranteed mechanical characteristics

- Tensile strenght ≥ 300 MPa - Rm

- Yield point ≥ 180 Mpa - R0.2

- Percentage elongation at break L0=5,65 √S0 ≥ 25%

- Cleanness and internal humidity acc. to DIN 8964

Standard packaging - Domestic market

- Coils are supplied on wooden pallets (expendable) or on galvanised steel pallets (to be returned).

They are laid with wraps parallel to the pallet surface, compactly wound.

Wraps are clamped and secured by suitable straps in three or four points.

The maximum weight for each pallet is about 2500 kg.

Cold-rolled strip coils are protected with anti-oxidation oil.

Standard packaging - for Export

- Cold-rolled strip compactly wound coils with anti-oxidation oil are supplied in V.C.I. bag.

Coils are laid with wraps parallel to the pallets surface, compactly wound.

Marcegaglia Imat

Marcegaglia IMAT is the specialised unit for the design and creation of components and systems for the refrigeration and electrical appliance industry, with a wide and synergic range of products for the cooling system, from condensation to evaporation right up to covering the growing needs of heat pump circuits.

Thanks to the product and process know-how matured over 40 years of activity, Marcegaglia IMAT can work alongside its clientele as a partner during the product’s co-design development processes, guaranteeing the supply of complex components and systems with the highest standards of quality and performance.

Contact us

Would you life further information?

Our Technical Department is here to illustrate the product’s potentials and listen to your every request.

"*" indicates required fields